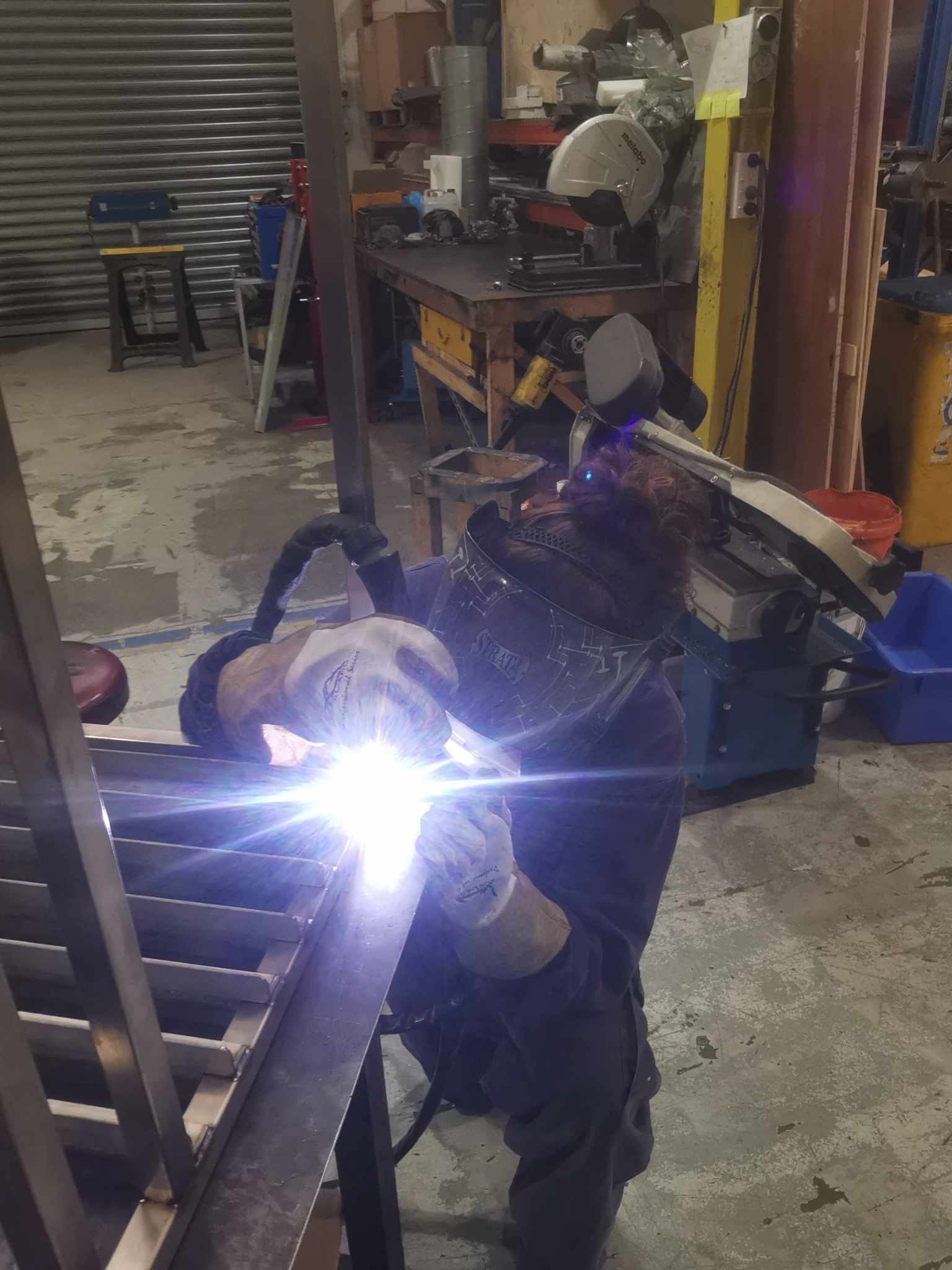

Skills: System Design, Health and Safety, Welding, Fabricating Skills

A 12-week internship that involved using design-led processes to implement new aspects of a health and safety system for the company. In addition to this, the internship has included consulting with people in the organization, contributing to the company's production processes through welding, fabrication, and learning about how 3D printing can be utilized to print new chemical fibers.

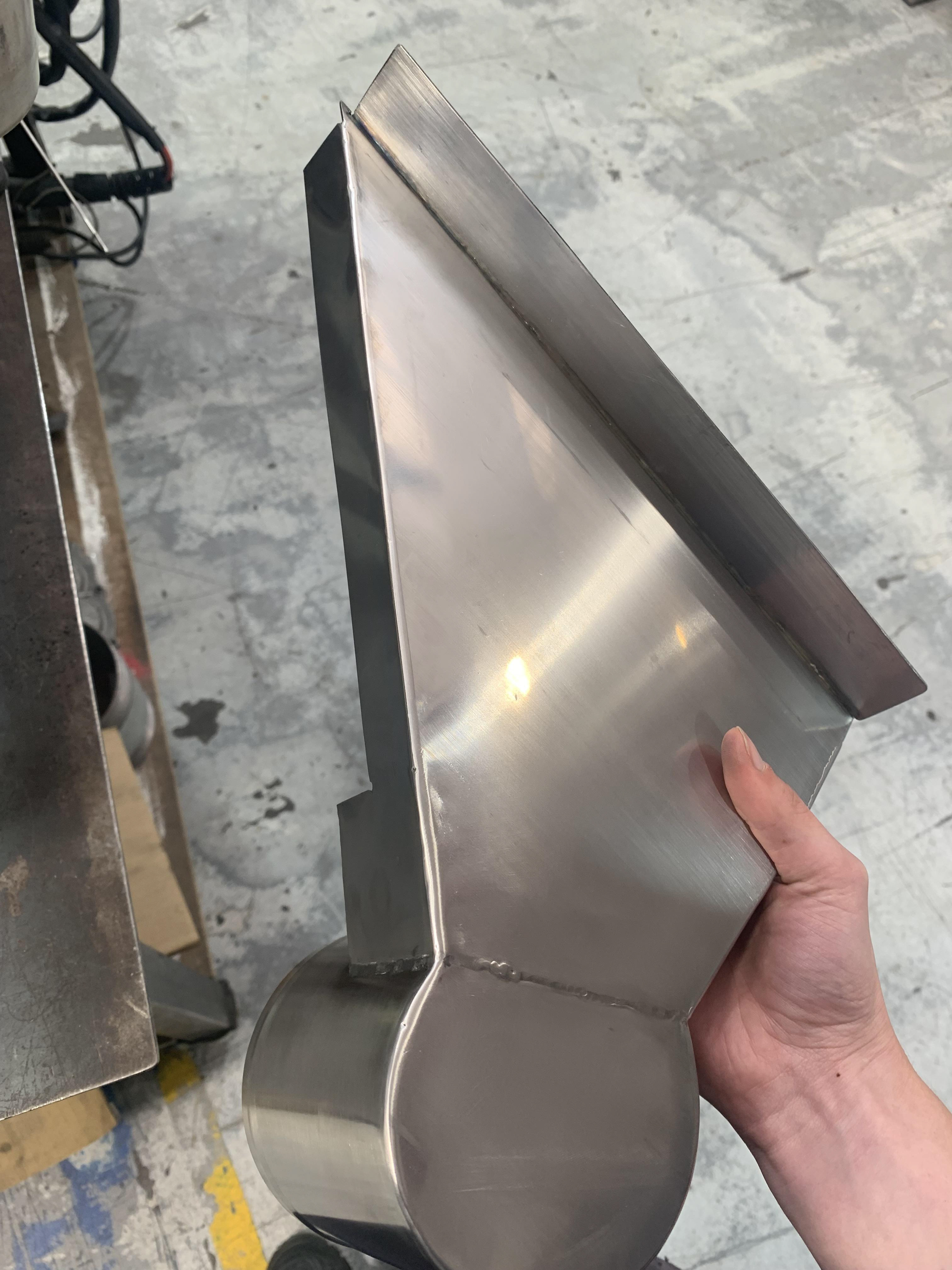

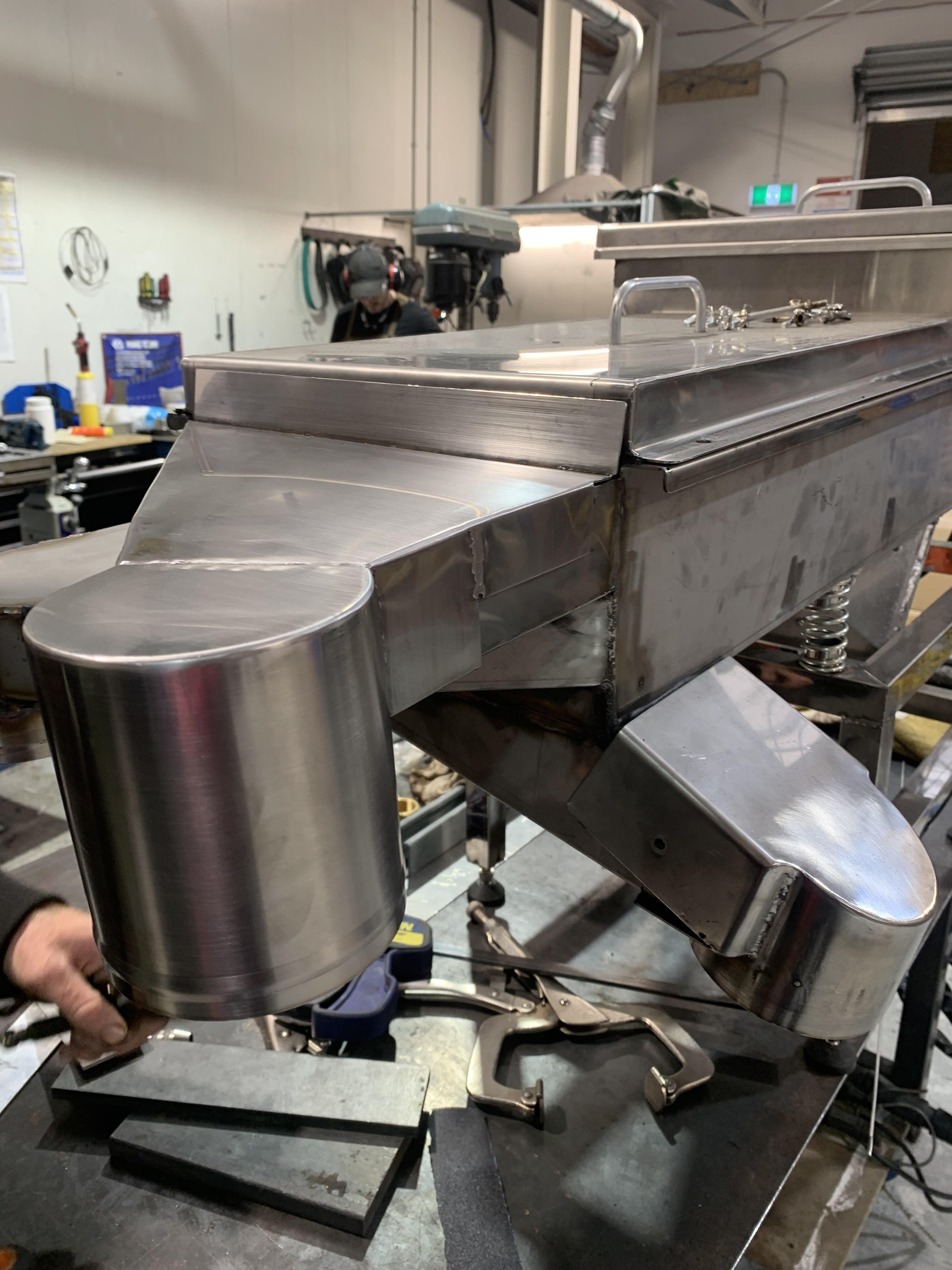

Fabricating Additions to the shaker device.

Process: Weld overhanging edges, use an angle grinder to sand down edges, and then polish sections to create the illusion of one piece that has been bent rather than two pieces that have been welded together.

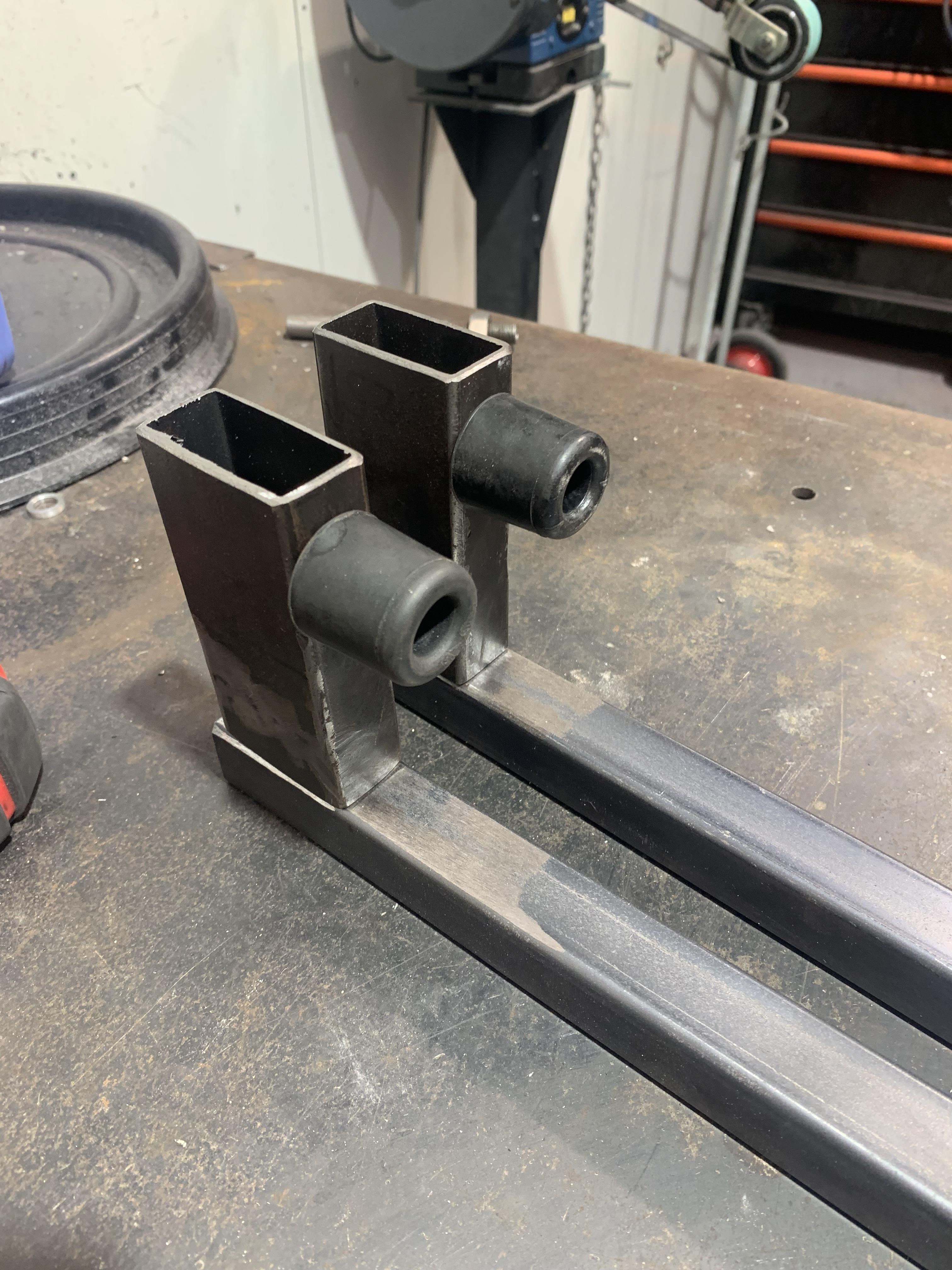

Fabricating extensions for the stops on one of the furnaces so that the trolley could be pulled out further to allow for more efficient loading and unloading.

Process: Cut scrap metal pieces to size using the horizontal bandsaw, sand away old grime and uneven surfaces, weld pieces together, drill holes for bolts, spray paint, and final attachment to the furnace.

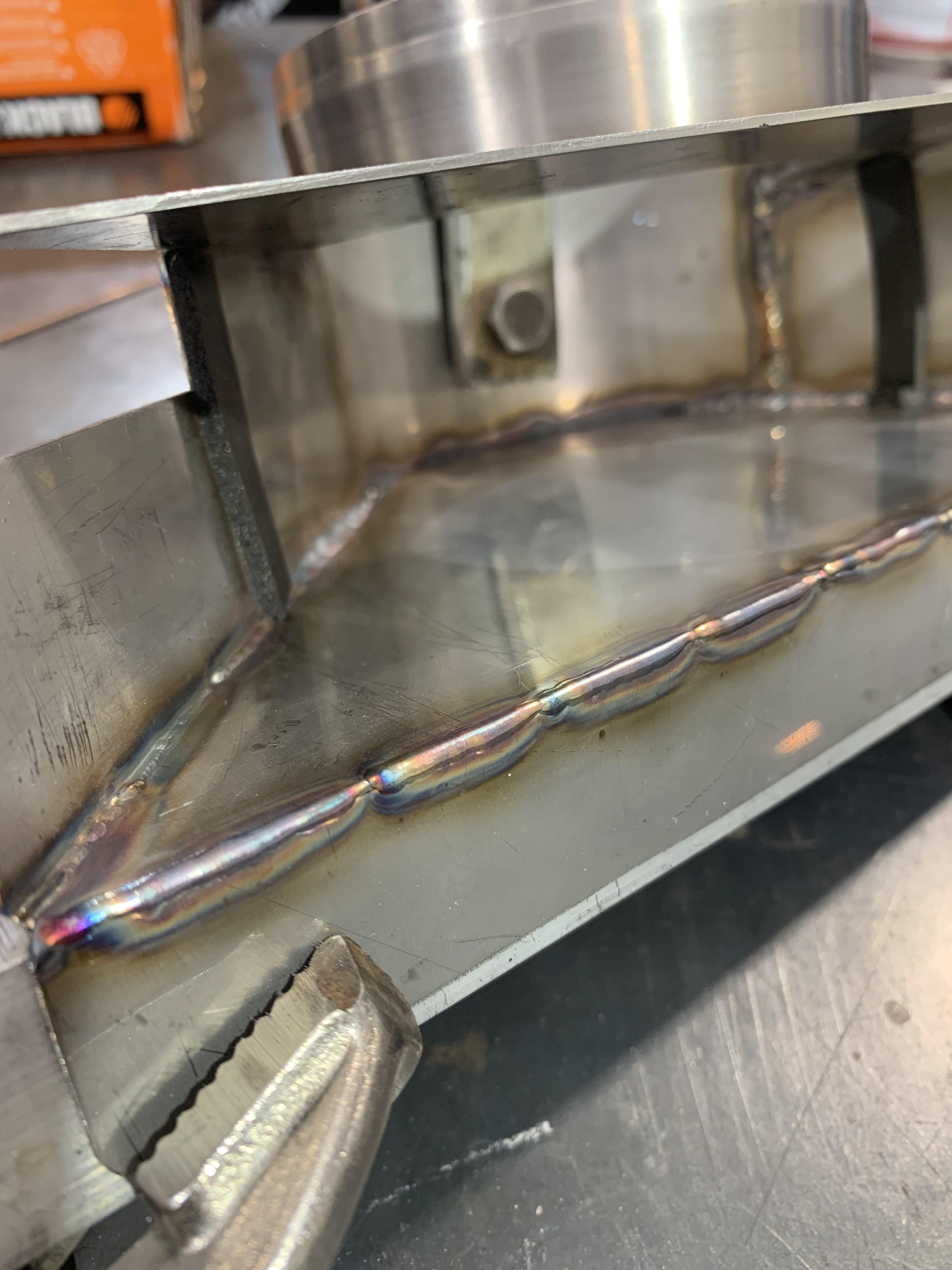

Left: Tig Welding

Right: First-time welding with Aluminium

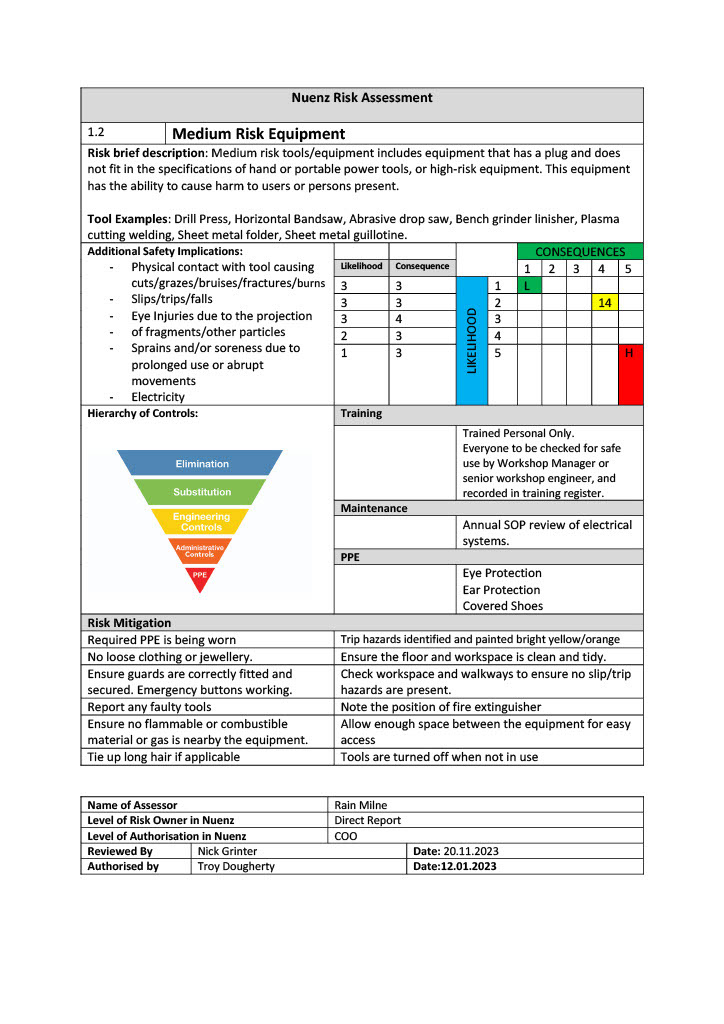

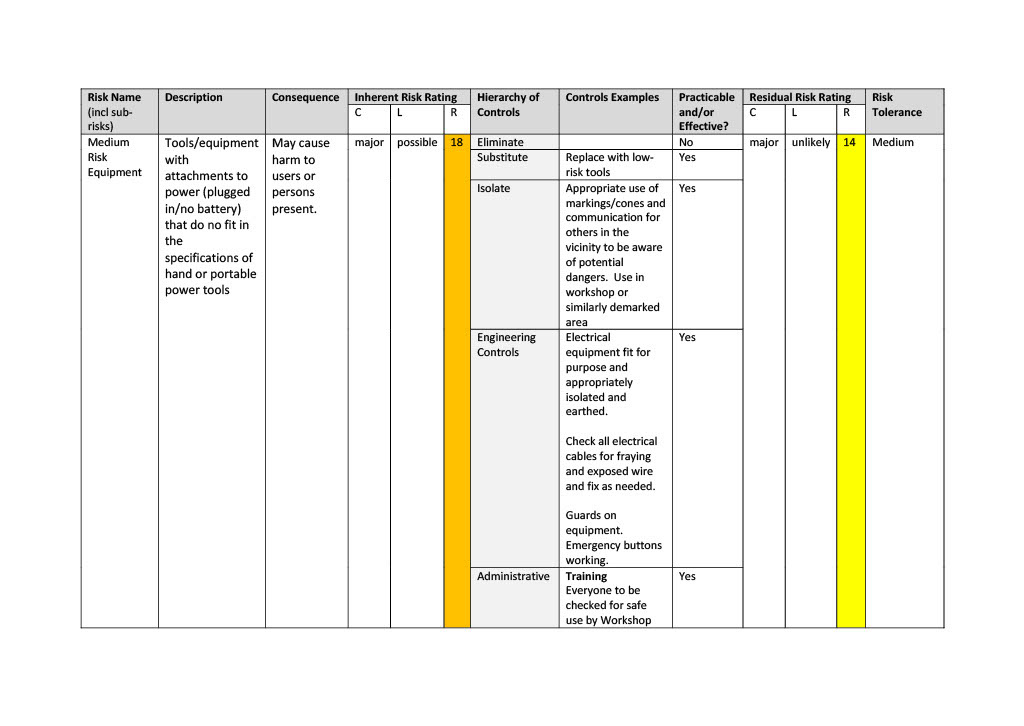

Base template of the risk types requiring written risk assessment reports using the hieracy of controls. These reports will then be implemented into a new health and safety system. Other tasks included updating SOPs (Standard Operating Procedures) and simplifying chemical safety sheets into to summarised single-page posters to reduce the time needed to find important safety information in case of an accident (e.g. a fire near a chemical or the spillage of dangerous fibres).